Carton / Stainless Steel Multi-Wave Compression Spring-Wave Springs Standard 60mm

Carton / stainless steel Multi-Wave Compression Spring-Wave Springs standard 60mm

Description:

1,Wave springs help to save up to 50% of axial space in your application when compared to conventional coil springs. The result is more compact applications in which unnecessary space and therefore excess material of neighboring components can be reduced to a minimum.

2,The flat wire effectively reduces the solid height of the wave spring so that with the same amount of turns one can visibly reduce the work height without compromising the load or spring deflection.

3,Another advantage is that one can increase the number of turns of the spring design in order to decrease the deflection per turn when the wave spring is compressed. Thus, the spring rate is reduced proportionally to the number of turns and a flat linear characteristic can be generated.

Specification:

| Part No. | Operates in Bore Diameter | Lears Shaft Diameter | Load | Work Height | Free Height | Waves | Turns | Thinkness | Radial Wall | Spring Rate |

| mm | mm | (N) | mm | mm | mm | mm | N/MM | |||

| LM60-H1 | 60 | 50 | 450 | 7.75 | 11.43 | 4.5 | 3 | 0.76 | 4.01 | 122.28 |

| LM60-L1 | 60 | 50 | 135 | 5.59 | 11.43 | 4.5 | 3 | 0.46 | 3.63 | 23.12 |

| LM60-M1 | 60 | 50 | 275 | 6.65 | 11.43 | 4.5 | 3 | 0.61 | 3.76 | 57.53 |

| LM60-H2 | 60 | 50 | 450 | 10.31 | 15.24 | 4.5 | 4 | 0.76 | 4.01 | 91.28 |

| LM60-L2 | 60 | 50 | 135 | 7.47 | 15.24 | 4.5 | 4 | 0.46 | 3.63 | 17.37 |

| LM60-M2 | 60 | 50 | 275 | 8.86 | 15.24 | 4.5 | 4 | 0.61 | 3.76 | 43.1 |

| LM60-H3 | 60 | 50 | 450 | 12.9 | 19.05 | 4.5 | 5 | 0.76 | 4.01 | 73.17 |

| LM60-L3 | 60 | 50 | 135 | 9.32 | 19.05 | 4.5 | 5 | 0.46 | 3.63 | 13.87 |

| LM60-M3 | 60 | 50 | 275 | 11.07 | 19.05 | 4.5 | 5 | 0.61 | 3.76 | 34.46 |

| LM60-H4 | 60 | 50 | 450 | 15.47 | 22.86 | 4.5 | 6 | 0.76 | 4.01 | 60.89 |

| LM60-L4 | 60 | 50 | 135 | 11.2 | 22.86 | 4.5 | 6 | 0.46 | 3.63 | 11.58 |

| LM60-M4 | 60 | 50 | 275 | 13.28 | 22.86 | 4.5 | 6 | 0.61 | 3.76 | 28.71 |

| LM60-H5 | 60 | 50 | 450 | 18.06 | 26.67 | 4.5 | 7 | 0.76 | 4.01 | 52.26 |

| LM60-L5 | 60 | 50 | 135 | 13.06 | 26.67 | 4.5 | 7 | 0.46 | 3.63 | 9.92 |

| LM60-M5 | 60 | 50 | 275 | 15.49 | 26.67 | 4.5 | 7 | 0.61 | 3.76 | 24.6 |

| LM60-H6 | 60 | 50 | 450 | 20.62 | 30.48 | 4.5 | 8 | 0.76 | 4.01 | 45.64 |

| LM60-L6 | 60 | 50 | 135 | 14.94 | 30.48 | 4.5 | 8 | 0.46 | 3.63 | 8.69 |

| LM60-M6 | 60 | 50 | 275 | 17.7 | 30.48 | 4.5 | 8 | 0.61 | 3.76 | 21.52 |

| LM60-H7 | 60 | 50 | 450 | 23.22 | 34.29 | 4.5 | 9 | 0.76 | 4.01 | 40.65 |

| LM60-L7 | 60 | 50 | 135 | 16.79 | 34.29 | 4.5 | 9 | 0.46 | 3.63 | 7.71 |

| LM60-M7 | 60 | 50 | 275 | 19.94 | 34.29 | 4.5 | 9 | 0.61 | 3.76 | 19.16 |

| LM60-H8 | 60 | 50 | 450 | 28.37 | 41.91 | 4.5 | 11 | 0.76 | 4.01 | 33.23 |

| LM60-L8 | 60 | 50 | 135 | 20.52 | 41.91 | 4.5 | 11 | 0.46 | 3.63 | 6.31 |

| LM60-M8 | 60 | 50 | 275 | 24.36 | 41.91 | 4.5 | 11 | 0.61 | 3.76 | 15.67 |

| LM60-H9 | 60 | 50 | 450 | 33.53 | 49.53 | 4.5 | 13 | 0.76 | 4.01 | 28.13 |

| LM60-L9 | 60 | 50 | 135 | 24.26 | 49.53 | 4.5 | 13 | 0.46 | 3.63 | 5.34 |

| LM60-M9 | 60 | 50 | 275 | 28.78 | 49.53 | 4.5 | 13 | 0.61 | 3.76 | 13.25 |

| LM60-H10 | 60 | 50 | 450 | 38.68 | 57.15 | 4.5 | 15 | 0.76 | 4.01 | 24.36 |

| LM60-L10 | 60 | 50 | 135 | 27.99 | 57.15 | 4.5 | 15 | 0.46 | 3.63 | 4.63 |

| LM60-M10 | 60 | 50 | 275 | 33.22 | 57.15 | 4.5 | 15 | 0.61 | 3.76 | 11.49 |

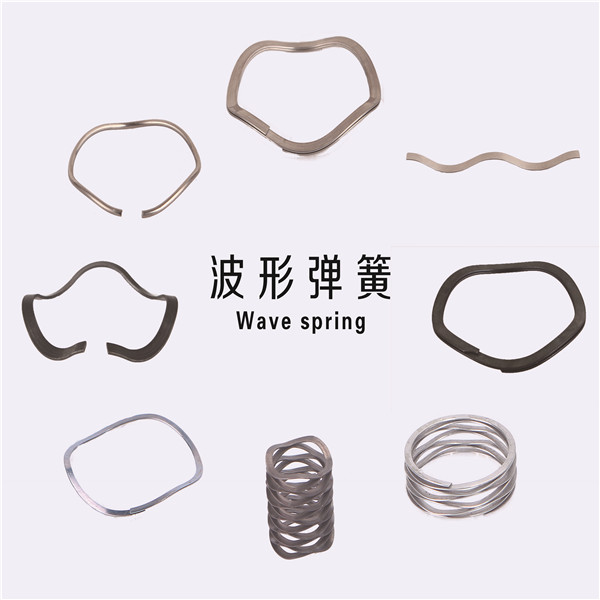

Advantage of wave springs

1,No material waste compared to stamped parts

2,Rolled flat wire features edges with a radius—NO DAMAGE TO SHAFT/BORE

3,No stamping burrs eliminates the grinding process

4,No stamping through the metal grain--microstructures remain intact

5,Microstructure offers better strength because the line of force in circumferential direction is not disturbed; risk of fatigue cracking and inconsistent loading in a lot is minimized.

Zhejiang Lisheng Spring Co.,Ltd

Zhejiang lisheng spring Co., Ltd, began to produce all kinds of spring and hardware products in 2009. It is a member enterprise of China Spring Association. The company has been working hard to strive to improve the enterprise concept.In 2012, we began to develop wave spring, spiral retaining ring and seal ring.

Our company has introduced wave spring design software system from Germany.Our engineers can use cable element analysis software for performance analysis.We can quickly design the non-standard products as you need.

At present, our company keeps thousands of products of regular size in stock.Since the company imported Japanese wave spring 、snap ring machine, you can quickly produce non-standard products without making extra molds.

Our products are mainly used in the fields of aerospace, automobile, petroleum, medical equipment, wind energy, engineering machinery, consumer electronics and other industrial products.

The company feedback customers with the quality policy of customer first, full participation, continuous improvement and pursuit of excellence. The products are not only well received by domestic customers, but also exported to European and American countries.In the credit, service aspect also obtains the customer's consistent high praise.