Single Turn Gap Type Wave Springs SSR Series

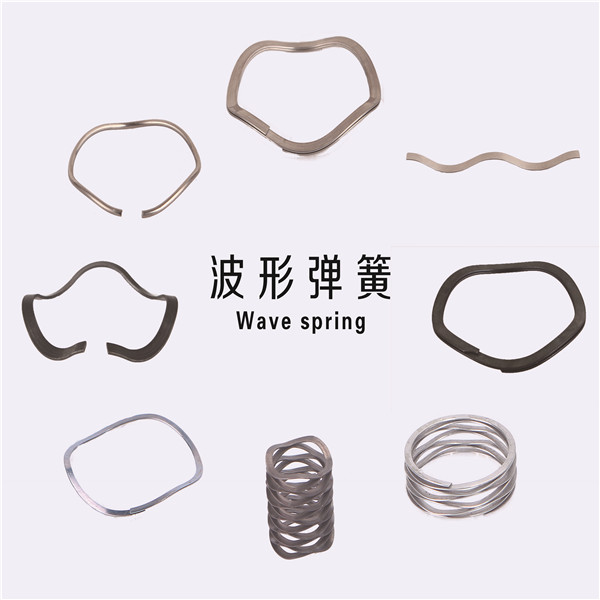

Description:

Conventional Gap and Overlap Type Wave Springs are used in a wide variety of applications. For short deflections and low-medium forces, they function with precision and dependability.

These two types of Wave Springs permit radial expansion or growth in diameter within a cavity, without the binding or hang-up normally associated with die stamped wave washers. Just as their terms imply, the gap type is split to retain a gap between the ends; while the overlap type has overlapping ends. Thus, the ends are free to move circumferentially as the spring outside diameter grows during compression.

For example, the O.D. of a Gap Type Wave Spring would fit .020 loose per side in a bore. Its I.D. clears a shaft by .010 per side. As the spring is deflected, the O.D. and I.D. grow larger until the O.D. contacts the bore. Continued deflection causes the gap ends to move closer together while the O.D. presses against the bore. An Overlap Type Wave Spring permits this type of cycling action in a similar manner.

Surface finish option

Nickel plating, chrome plating, zinc plating, galvanization ,passivation, ultrasonic washing,silver plating,gold plating,electrophoresis,phosphorization, dacromet, teflon coating etc

Specification:

| Part Number | Operates in Bore Diameter(inch) | Clears Shaft Diameter(inch) | Load(lb) | Work Height(inch) | Free Height (inch) | Number of Waves | Thickness (inch) | Radial Wall(inch) | Spring Rate (inch/lb) |

| SSR-0050 | 0.5 | 0.39 | 7 | 0.05 | 0.085 | 3 | 0.008 | 0.04 | 200 |

| SSR-0062 | 0.625 | 0.48 | 10 | 0.05 | 0.095 | 3 | 0.01 | 0.058 | 222 |

| SSR-0075 | 0.75 | 0.5 | 14 | 0.062 | 0.16 | 3 | 0.01 | 0.078 | 143 |

| SSR-0087 | 0.875 | 0.62 | 16 | 0.062 | 0.13 | 3 | 0.012 | 0.094 | 235 |

| SSR-0100 | 1 | 0.78 | 18 | 0.062 | 0.16 | 3 | 0.012 | 0.094 | 184 |

| SSR-0112 | 1.125 | 0.84 | 20 | 0.078 | 0.13 | 3 | 0.016 | 0.133 | 385 |

| SSR-0125 | 1.25 | 0.96 | 22 | 0.078 | 0.15 | 3 | 0.016 | 0.133 | 306 |

| SSR-0137 | 1.375 | 1.09 | 24 | 0.078 | 0.19 | 3 | 0.016 | 0.133 | 214 |

| SSR-0150 | 1.5 | 1.17 | 26 | 0.078 | 0.17 | 3 | 0.018 | 0.143 | 283 |

| SSR-0162 | 1.625 | 1.31 | 28 | 0.078 | 0.2 | 3 | 0.018 | 0.143 | 230 |

| SSR-0175 | 1.75 | 1.44 | 30 | 0.078 | 0.14 | 4 | 0.018 | 0.143 | 484 |

| SSR-0187 | 1.875 | 1.56 | 32 | 0.078 | 0.15 | 4 | 0.018 | 0.143 | 444 |

| SSR-0200 | 2 | 1.68 | 34 | 0.093 | 0.14 | 4 | 0.024 | 0.15 | 723 |

| SSR-0212 | 2.125 | 1.8 | 36 | 0.093 | 0.15 | 4 | 0.024 | 0.15 | 632 |

| SSR-0225 | 2.25 | 1.93 | 38 | 0.093 | 0.17 | 4 | 0.024 | 0.15 | 494 |

| SSR-0237 | 2.375 | 1.99 | 40 | 0.093 | 0.16 | 4 | 0.024 | 0.178 | 597 |

| SSR-0250 | 2.5 | 2.12 | 42 | 0.093 | 0.17 | 4 | 0.024 | 0.178 | 545 |

| SSR-0262 | 2.625 | 2.24 | 44 | 0.093 | 0.19 | 4 | 0.024 | 0.178 | 454 |

| SSR-0275 | 2.75 | 2.34 | 46 | 0.109 | 0.17 | 4 | 0.03 | 0.188 | 754 |

| SSR-0287 | 2.875 | 2.47 | 48 | 0.109 | 0.18 | 4 | 0.03 | 0.188 | 676 |

| SSR-0300 | 3 | 2.59 | 50 | 0.109 | 0.19 | 4 | 0.03 | 0.188 | 617 |

| SSR-0312 | 3.125 | 2.71 | 52 | 0.109 | 0.21 | 4 | 0.03 | 0.188 | 515 |

| SSR-0325 | 3.25 | 2.75 | 54 | 0.109 | 0.2 | 4 | 0.03 | 0.233 | 593 |

| SSR-0337 | 3.375 | 2.84 | 56 | 0.109 | 0.22 | 4 | 0.03 | 0.233 | 505 |

| SSR-0350 | 3.5 | 3 | 58 | 0.109 | 0.23 | 4 | 0.03 | 0.233 | 479 |

| SSR-0362 | 3.625 | 3.12 | 60 | 0.109 | 0.24 | 4 | 0.03 | 0.233 | 458 |

| SSR-0375 | 3.75 | 3.25 | 62 | 0.109 | 0.26 | 4 | 0.03 | 0.233 | 411 |

| SSR-0387 | 3.875 | 3.37 | 64 | 0.109 | 0.3 | 4 | 0.03 | 0.233 | 335 |

| SSR-0400 | 4 | 3.5 | 66 | 0.109 | 0.19 | 5 | 0.03 | 0.233 | 815 |

| SSR-0412 | 4.125 | 3.62 | 67 | 0.109 | 0.2 | 5 | 0.03 | 0.233 | 736 |

| SSR-0425 | 4.25 | 3.74 | 69 | 0.109 | 0.21 | 5 | 0.03 | 0.233 | 683 |

| SSR-0437 | 4.375 | 3.86 | 70 | 0.109 | 0.21 | 5 | 0.03 | 0.233 | 693 |

| SSR-0450 | 4.5 | 3.99 | 72 | 0.109 | 0.23 | 5 | 0.03 | 0.233 | 595 |

| SSR-0462 | 4.625 | 4.11 | 73 | 0.125 | 0.27 | 5 | 0.03 | 0.233 | 503 |

| SSR-0475 | 4.75 | 4.24 | 75 | 0.125 | 0.31 | 5 | 0.03 | 0.233 | 405 |

| SSR-0487 | 4.875 | 4.37 | 76 | 0.125 | 0.29 | 5 | 0.03 | 0.233 | 461 |

| SSR-0500 | 5 | 4.49 | 78 | 0.125 | 0.31 | 5 | 0.03 | 0.233 | 422 |

| SSR-0512 | 5.125 | 4.61 | 80 | 0.125 | 0.34 | 5 | 0.03 | 0.233 | 372 |

| SSR-0525 | 5.25 | 4.74 | 82 | 0.125 | 0.37 | 5 | 0.03 | 0.233 | 335 |

| SSR-0537 | 5.375 | 4.86 | 84 | 0.125 | 0.38 | 5 | 0.03 | 0.233 | 329 |

| SSR-0550 | 5.5 | 4.99 | 86 | 0.125 | 0.25 | 6 | 0.03 | 0.233 | 688 |

| SSR-0562 | 5.625 | 5.11 | 88 | 0.125 | 0.27 | 6 | 0.03 | 0.233 | 607 |

| SSR-0575 | 5.75 | 5.24 | 90 | 0.125 | 0.28 | 6 | 0.03 | 0.233 | 581 |

| SSR-0587 | 5.875 | 5.36 | 92 | 0.125 | 0.3 | 6 | 0.03 | 0.233 | 526 |

| SSR-0600 | 6 | 5.49 | 94 | 0.125 | 0.3 | 6 | 0.03 | 0.233 | 537 |

| SSR-0612 | 6.125 | 5.61 | 96 | 0.125 | 0.31 | 6 | 0.03 | 0.233 | 519 |

| SSR-0625 | 6.25 | 5.73 | 98 | 0.125 | 0.34 | 6 | 0.03 | 0.233 | 456 |

| SSR-0637 | 6.375 | 5.86 | 100 | 0.125 | 0.35 | 6 | 0.03 | 0.233 | 444 |

| SSR-0650 | 6.5 | 5.98 | 102 | 0.125 | 0.39 | 6 | 0.03 | 0.233 | 385 |

| SSR-0675 | 6.75 | 6.23 | 104 | 0.125 | 0.42 | 6 | 0.03 | 0.233 | 353 |

| SSR-0700 | 7 | 6.16 | 106 | 0.156 | 0.32 | 6 | 0.032 | 0.375 | 646 |

| SSR-0725 | 7.25 | 6.44 | 108 | 0.156 | 0.35 | 6 | 0.032 | 0.375 | 557 |

| SSR-0750 | 7.5 | 6.69 | 110 | 0.156 | 0.36 | 6 | 0.032 | 0.375 | 539 |

| SSR-0775 | 7.75 | 6.94 | 114 | 0.156 | 0.38 | 6 | 0.032 | 0.375 | 509 |

| SSR-0800 | 8 | 7.19 | 118 | 0.156 | 0.39 | 6 | 0.032 | 0.375 | 504 |

| SSR-0825 | 8.25 | 7.44 | 122 | 0.156 | 0.43 | 6 | 0.032 | 0.375 | 445 |

| SSR-0850 | 8.5 | 7.68 | 126 | 0.156 | 0.34 | 7 | 0.032 | 0.375 | 685 |

| SSR-0875 | 8.75 | 7.93 | 130 | 0.156 | 0.34 | 7 | 0.032 | 0.375 | 707 |

| SSR-0900 | 9 | 8.18 | 134 | 0.156 | 0.29 | 8 | 0.032 | 0.375 | 1000 |

| SSR-0950 | 9.5 | 8.68 | 142 | 0.156 | 0.24 | 9 | 0.032 | 0.375 | 1690 |

| SSR-1000 | 10 | 9.17 | 150 | 0.156 | 0.29 | 9 | 0.032 | 0.375 | 1119 |

| SSR-1050 | 10.5 | 9.67 | 158 | 0.156 | 0.31 | 9 | 0.032 | 0.375 | 1026 |

| SSR-1100 | 11 | 10.17 | 166 | 0.156 | 0.35 | 9 | 0.032 | 0.375 | 856 |

| SSR-1150 | 11.5 | 10.66 | 174 | 0.156 | 0.36 | 9 | 0.032 | 0.375 | 853 |

| SSR-1200 | 12 | 11.16 | 182 | 0.156 | 0.44 | 9 | 0.032 | 0.375 | 641 |

| SSR-1250 | 12.5 | 11.66 | 190 | 0.156 | 0.35 | 10 | 0.032 | 0.375 | 979 |

| SSR-1300 | 13 | 12.16 | 198 | 0.156 | 0.41 | 10 | 0.032 | 0.375 | 780 |

| SSR-1350 | 13.5 | 12.65 | 206 | 0.156 | 0.43 | 10 | 0.032 | 0.375 | 752 |

| SSR-1400 | 14 | 13.15 | 214 | 0.156 | 0.3 | 12 | 0.032 | 0.375 | 1486 |

| SSR-1450 | 14.5 | 13.65 | 221 | 0.156 | 0.32 | 12 | 0.032 | 0.375 | 1348 |

| SSR-1500 | 15 | 14.13 | 230 | 0.156 | 0.35 | 12 | 0.032 | 0.375 | 1186 |

| SSR-1550 | 15.5 | 14.64 | 239 | 0.156 | 0.31 | 13 | 0.032 | 0.375 | 1552 |

| SSR-1600 | 16 | 15.14 | 248 | 0.156 | 0.34 | 13 | 0.032 | 0.375 | 1348 |

Zhejiang Lisheng Spring Co.,Ltd

Zhejiang lisheng spring Co., Ltd, began to produce all kinds of spring and hardware products in 2009. It is a member enterprise of China Spring Association. The company has been working hard to strive to improve the enterprise concept.In 2012, we began to develop wave spring, spiral retaining ring and seal ring.

Our company has introduced wave spring design software system from Germany.Our engineers can use cable element analysis software for performance analysis.We can quickly design the non-standard products as you need.

At present, our company keeps thousands of products of regular size in stock.Since the company imported Japanese wave spring 、snap ring machine, you can quickly produce non-standard products without making extra molds.

Our products are mainly used in the fields of aerospace, automobile, petroleum, medical equipment, wind energy, engineering machinery, consumer electronics and other industrial products.

The company feedback customers with the quality policy of customer first, full participation, continuous improvement and pursuit of excellence. The products are not only well received by domestic customers, but also exported to European and American countries.In the credit, service aspect also obtains the customer's consistent high praise.