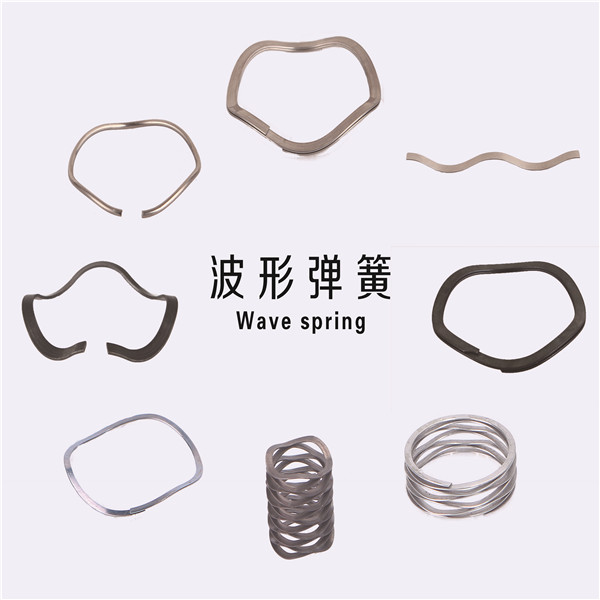

Customized Flat Wire Compression Overlapping Wave Spring Washers Sizes

Customized flat wire compression Overlapping wave spring washers sizes

Material Finishes:

1.Passivation

Passivation is an optional cleaning operation for stainless steel. It provides a bright finish and increased corrosion resistance. Passivation dissolves iron particles and other substances, which have become imbedded in the surface of stainless steel during production. If not dissolved, these foreign particles could promote rusting, discoloration or even pitting.

2.Vapor Degrease/Ultrasoni

This is the standard cleaning and finish for all stainless steels. The process removes oil and other organic compounds from the material surface by use of a chlorinated solvent. The solvent effectively removes oil and grease from the exposed surfaces of the ring or spring. Ultrasonics are used in forcing the solvent to act between the turns of the ring.

3.Vibratory Deburr/Hand Deburr

Though all circumferential surfaces and edges of Spirolox Rings are smooth, sharp corners are always present on the gap ends due to the cut-off operation. To break the sharp corners, achieving a blended/smooth surface finish, rings may either be vibratory or hand deburred to meet your specifications.

Specification:

| Part No. | Operates in Bore Diameter | Lears Shaft Diameter | Load | Work Height | Free Height | Waves | Thinkness | Radial Wall | Spring Rate | Open mode |

| mm | mm | (N) | mm | mm | mm | mm | N/MM | |||

| JBT-042 | 42 | - | 205-295 | 1.5 | 2.7 | 4 | 0.53 | 3.63 | - | overlap |

| LB-0165 | 42 | 33.72 | 115.7 | 1.98 | 3.05 | 4 | 0.46 | 3.63 | 99 | overlap |

| LR-0175 | 44.45 | 36.58 | 133.36 | 1.98 | 3.56 | 4 | 0.46 | 3.63 | 84.7 | gap |

| JBT-047 | 47 | - | 225-315 | 1.5 | 3.4 | 4 | 0.59 | 3.23 | - | overlap |

| LB-0185 | 47 | 38.72 | 129 | 1.98 | 3.81 | 4 | 0.46 | 3.63 | 68 | overlap |

| LR-0187 | 47.63 | 39.62 | 142.25 | 1.98 | 3.81 | 4 | 0.46 | 3.63 | 77.7 | gap |

| LR-0200 | 50.8 | 42.67 | 151.14 | 2.36 | 3.56 | 4 | 0.61 | 3.81 | 126.53 | gap |

| LB-0453 | 115 | 101.38 | 315.9 | 3.18 | 6.35 | 5 | 0.76 | 5.92 | 99 | gap |

| LR-0462 | 117.48 | 104.39 | 324.51 | 3.18 | 6.86 | 5 | 0.76 | 5.92 | 88.03 | gap |

| LR-0462-N | 117.48 | 106.43 | 324.51 | 3.18 | 6.86 | 5 | 0.76 | 4.78 | 88.03 | gap |

| JBT-120 | 120 | - | 515-625 | 2 | 5.8 | 6 | 0.76 | 4.78 | - | gap |

| LB-0472 | 120 | 106.38 | 329.3 | 3.18 | 7.11 | 5 | 0.76 | 5.92 | 86 | gap |

| LR-0475 | 120.65 | 107.7 | 333.4 | 3.18 | 7.87 | 5 | 0.76 | 5.92 | 70.88 | gap |

| LR-0475-N | 120.65 | 109.73 | 333.4 | 3.18 | 8.13 | 5 | 0.76 | 4.78 | 67.38 | gap |

| LR-0487 | 123.83 | 111 | 337.84 | 3.18 | 7.37 | 5 | 0.76 | 5.92 | 80.68 | gap |

| LR-0487-N | 123.83 | 112.78 | 337.84 | 3.18 | 8.13 | 5 | 0.76 | 4.78 | 68.25 | gap |

| JBT-125 | 125 | - | 515-625 | 2 | 6.2 | 6 | 0.76 | 4.78 | - | gap |

| LB-0492 | 125 | 111.38 | 342.6 | 3.18 | 7.62 | 5 | 0.76 | 5.92 | 76 | gap |

| LR-0500 | 127 | 114.05 | 346.73 | 3.18 | 7.87 | 5 | 0.76 | 5.92 | 73.85 | gap |

| LR-0500-N | 127 | 116.08 | 346.73 | 3.18 | 8.89 | 5 | 0.76 | 4.78 | 60.73 | gap |

| JBT-130 | 130 | - | 525-635 | 3 | 4.7 | 6 | 0.87 | 6.33 | - | gap |

Factory introduction:

The company has successfully passed ISO9001 and IATF16949 quality management system certification. Our wave springs and spiral retaining rings are mainly used in aerospace, automobile, petroleum, medical equipment, wind energy, construction machinery, consumer electronics and other industrial products .

Zhejiang Lisheng Spring Co.,Ltd

Zhejiang lisheng spring Co., Ltd, began to produce all kinds of spring and hardware products in 2009. It is a member enterprise of China Spring Association. The company has been working hard to strive to improve the enterprise concept.In 2012, we began to develop wave spring, spiral retaining ring and seal ring.

Our company has introduced wave spring design software system from Germany.Our engineers can use cable element analysis software for performance analysis.We can quickly design the non-standard products as you need.

At present, our company keeps thousands of products of regular size in stock.Since the company imported Japanese wave spring 、snap ring machine, you can quickly produce non-standard products without making extra molds.

Our products are mainly used in the fields of aerospace, automobile, petroleum, medical equipment, wind energy, engineering machinery, consumer electronics and other industrial products.

The company feedback customers with the quality policy of customer first, full participation, continuous improvement and pursuit of excellence. The products are not only well received by domestic customers, but also exported to European and American countries.In the credit, service aspect also obtains the customer's consistent high praise.